Time of Flight Diffraction (TOFD) is an advanced and automated weld examination technique that assists in Fitness For Purpose (FFP) inspections. Using TOFD, the expert NDT team members at TCR-Kuwait perform amplitude-independent accurate flaw sizing on a wide coverage area.

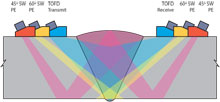

TOFD is a fast and efficient way to scan a lot of weld area in a very short time period. Dead zones near the front and back surface can be enhanced using combined TOFD and conventional pulse echo techniques.

The Time of Flight Diffraction (ToFD) technique is based on ultrasound, which, in contrast to manual pulse-echo examination, uses received diffraction signals instead of received reflected signals. TOFD is very sensitive to detecting all kinds of defects, irrespective of its orientation. Using this advanced technique gas and binding defects, porosity, slag inclusions and cracks can be detected independent of defect orientation with very accurate sizing of the defects (±0.5-1.0 mm).

In service validation and FPP projects ToFD has proved itself to be an acceptable technique, combining the high detection rate with a very high reliability in pre-service and in-service inspections. The ability to have digital storage of all inspection data, TOFD enables future evaluation of the same weld at any time and ensures high reproducibility.

Accepted in the Industry

ASME Boiler and Pressure Vessel Standard Section VIII Code Case 2235-9 states that is acceptable to use the TOFD for Ultrasonic examination in accordance with ASME Section V, Article 4. ASME Code Case 2235-9 mentions about replacing RT with UT and has resulted in incorporating TOFD into pressure vessel work for both detection and sizing of flaws. This now allows TOFD to be used on all Section VIII pressure vessels.

API 579 in its current draft form states the Recommended Practice for Fitness-for-Service (The crack depth, length, angle and distance to other surface breaking or embedded cracks is typically determined using UT examination techniques, either TOFD or angle beam.

Draft-API 580 states the Risk Based Inspection Recommended Practice (Base Resource Document recommends automated ultrasonic shear wave testing as a highly effective inspection technique for crack detection and sizing. The capability of the Automated UT technique/type is evaluated using probability of detection (POD) curves from round-robins in the past where TOFD showed the best performance).

British Standards Institute's welding standards policy committee has created the BS 7706 as a guide for the calibration and setting-up of the Ultrasonic Time of Flight diffraction (TOFD) technique for defect detection, location and sizing of flaws. Another well documented guide is the Pr EN 583-6.

Standards and Codes

Code Review:

Time-of-Flight Diffraction and Pulse Echo Line Scanning

The British TOFD standard

BS 7706

The European TOFD standard draft,

ENV 583-6 NDT - Ultrasonic examination part 6

ASTM E-1961

ASTM E-1961: Standard Practice for Mechanized Ultrasonic Examination of Girth Welds Using Zonal Discrimination with Focused Search Units